Luxury Oven Bakery_LKO-12

Lijia gas oven is designed and produced by guangzhou shilou shengshi food machinery co., LTD. It has the advantages of fast heating, high thermal efficiency, uniform baking, energy saving and time saving.

1. The body design is luxurious and beautiful

2. Humanized sliding door, layered glass window, real-time control of the oven condition

3. Independent control of front fire and bottom fire

4. Layer type split structure, easy to disassemble and install

5. Independent burner

6. Stainless steel combustion tube, high temperature resistance, corrosion resistance, durable without deformation

7. Pulse ignition and flame detection system, high ignition rate

8. Heat dissipation plate, effective and timely play a role, prolong the service life

9. Accidental flameout or gas flameout, automatic glance, safety and worry

10. Universal caster, convenient and labor-saving

11. Using liquefied petroleum gas as fuel, high combustion thermal efficiency and energy saving

Technical parameters

|

Model |

Operating temperature (℃) |

Voltage (V) |

POWER (Kw) |

production (Kg/h) |

Size (mm) |

Weight (Kg) |

| LKO-12 |

20±5-400 |

220 |

75W |

11-13 |

1420*1040*680 |

152 |

|

LKO-24 |

20±5-400 |

220 |

150W |

22-26 |

1420*1040*1480 |

260 |

|

LKO-36 |

20±5-400 |

220 |

225W |

33-38 |

1420*1040*1730 |

362 |

|

LKO-39 |

20±5-400 |

220 |

225W |

49-53 |

1740*1040*1730 | 408 |

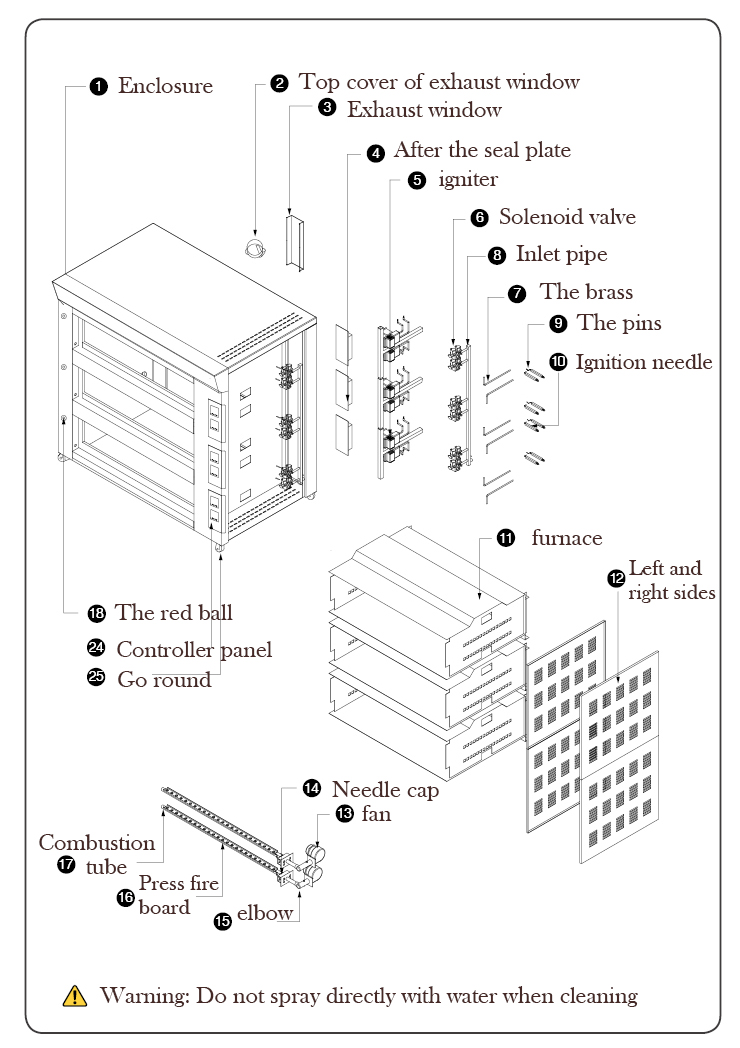

Product structure

The product installation

1. Place the oven on the level ground, so as not to cause the baking material inclined to the side due to the uneven surface of the oven.

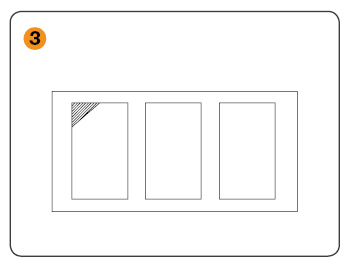

2. Place the fire control plate in the furnace in the correct position (the upper reflection plate is the "hole hole plate" in the center).

3. With exhaust pipe:

An exhaust pipe is installed on the back of the oven and fixed with screws. Users can buy aluminum bellows to fix the exhaust pipe on the exhaust pipe by themselves. The other end is pulled out of the window about 30cm, and the pipe outlet is drooped 10cm to prevent rain or other sundries from entering. Also make sure the oven is used in a well-ventilated environment.

Special note: this furnace consumes about 60 cubic meters of fresh air per hour, so be sure to keep adequate air circulation in the room, otherwise there is a risk of carbon monoxide poisoning.

4. Connect the gas pipe:

Connect the outlet of 15kg or 50kg liquefied petroleum cylinder with the large pressure regulating valve attached to the furnace, and then connect the gas pipe wrapped by the iron serpentine pipe to the copper nozzle of the gas pipe inlet of the oven by the pressure regulating valve. Both ends of the interface should be clamped tightly, and check the sealing of the pipeline (Note: the length of the gas pipe should not exceed 1 meter).

5. Contact:

This oven uses 220V AC power supply to power the control system and the lighting. Plug the plug into the 220V power supply. If the local power supply voltage is unstable, please use the power regulator.

Product Operation 1

1.Set all the furnace temperature to "000", connect the power supply, then the power indicator light is on, open the gas valve.

2.Turn on the main power switch of the oven, turn on the lighting switch, the lighting lamp in the oven is on, turn the knob as idle, set the target temperature value, and the red number shows the current temperature value.

3.Adjust the temperature controller of the bottom and surface fire. When the set temperature is higher than the actual temperature, the green light of the temperature meter ON will turn ON, and the furnace will start ignition and heating.

4.When heated to a predetermined temperature, the baked food can be put into the oven for baking, and the baked goods can be baked until they reach the degree of baking.

Product Operation 2

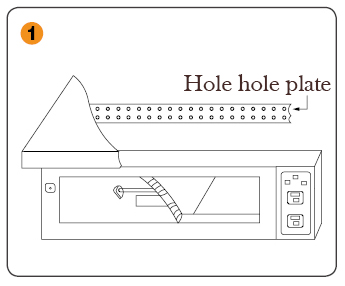

In order to ensure that the baked food is heated evenly, the upper part of the furnace is designed (as shown in Figure 1), and a fire control plate is installed at the lower part of the furnace. If uneven coloring of food is found in the baking process and is not caused by the baking pan and food distribution, adjust the fire plate to the appropriate position with an iron bar according to the degree of Browning of food.

Specific practices are as follows:

(1)adjustment of uniformity of upper fire

- When the fire appears before the white and after the black or before the black and after the white, the hole plate should be moved to the black side and the fire balance should be adjusted until. (See figure ②)

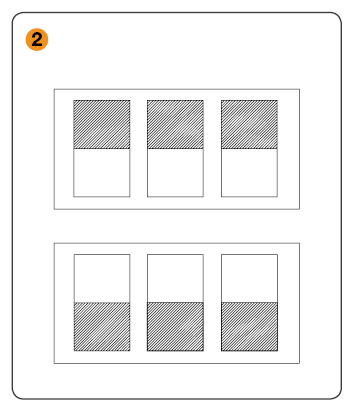

- If there is fire and one corner becomes black, move the left side of the hole plate to the direction of high fire, and the same problem occurs in other corners and so on. (see figure 3)

(2) the lower fire plate adjustment

Baking in the use of uneven heating at the bottom of the food, then after the furnace temperature drops, open the bottom plate, and then move the primer regulating plate to the place where the heat is too much, adjust to the uniform firepower.

General troubleshooting methods:

After the baking layer power is switched on, all kinds of indicator lights and display screens on the operation board are illuminated according to the operation. Ignition works in the furnace, and the oven works normally when the temperature of the furnace rises. If the indicator light and display screen do not shine or display abnormally during the operation, there is no fire in the furnace, and the heating temperature cannot be controlled, the oven is accompanied, and the following methods are used to detect:

|

The fault phenomenon |

The cause of the problem |

Failure analysis and troubleshooting |

|

The fire is lit and the color is normal, but the fire is extinguished after about 10 seconds and alarm is called |

A. Incorrect position of fire rod |

Adjust the position of the fire rod so that the flame reaches the fire rod |

|

B. The fire rod is damaged |

Replace with a new fire stick |

|

|

C. The microcomputer controller is broken |

Replace the IC microcomputer controller |

|

|

There was no fire at all, but there was a spark and a slight smell of gas |

A. Running out of gas or low pressure |

Change the gas bottle or soak the bottom of it in hot water below 80 C |

|

B. Temperature controller OFF red light Bright temperature display 300 degrees |

If the temperature sensor is in bad contact, lock the contact point between the temperature sensor and the temperature controller |

|

|

C. The microcomputer controller is damaged |

Switch with the normal IC microcomputer controller, can ignition combustion is normal, then replace the IC microcomputer controller |

|

|

D. Fan does not turn |

The flame becomes big and yellow. The fan doesn't turn. Change the fan |

|

|

Automatically extinguish and alarm during baking |

A. Too much air in (especially the first ignition on a cold day) |

Press the fan door with your hand to reduce the air entering the fan. If it can ignite, reduce the damper to the right amount (no need to adjust the damper in cold weather). |

|

B. Running out of gas or low pressure (especially in winter) |

Change the gas bottle or on cold days, soak the bottom of the gas bottle with hot water below 80 degrees |

|

|

C. The gas nozzle was clogged with debris |

Disassemble the copper gas nozzle on the gas valve and remove the sundry gas nozzle |

|

|

D. Solenoid valve after the fine - tuning pressure valve due to shock Moving and relaxing, resulting in too little gas entry |

Turn the fine tuning pressure valve on the solenoid valve clockwise downward to increase the gas volume |

Daily maintenance and service

1. After each baking, turn off the power to the oven and leave the door open to allow all steam to escape.

2. After the temperature in the machine drops, thoroughly clean the interior and transparent glass Windows. Do not use a wet cloth with corrosive detergent to clean the oven body, control panel and wires and cables. Direct flushing with water is also not allowed, so as not to damage the function.

3. Check the power cables and other electrical components regularly. If there is any damage, please contact the manufacturer or distributor in time.

4. If you're not using it at all, turn off the thermostat and main switch.

5. If the equipment is not used for a long time, store the equipment in a ventilated non-corrosive container after cleaning.